Understanding the differences between acid casein and rennet casein to improve formulation

Casein is a protein derived from the dairy industry, widely used in food formulation for its functional properties. Depending on the production method, its characteristics may vary, influencing its functionality and behaviour within food matrices. The aim of this article is to define the main types of casein, specifically acid casein and rennet casein, in order to determine which type is best suited for different applications.

Casein, a protein of interest

What is casein?

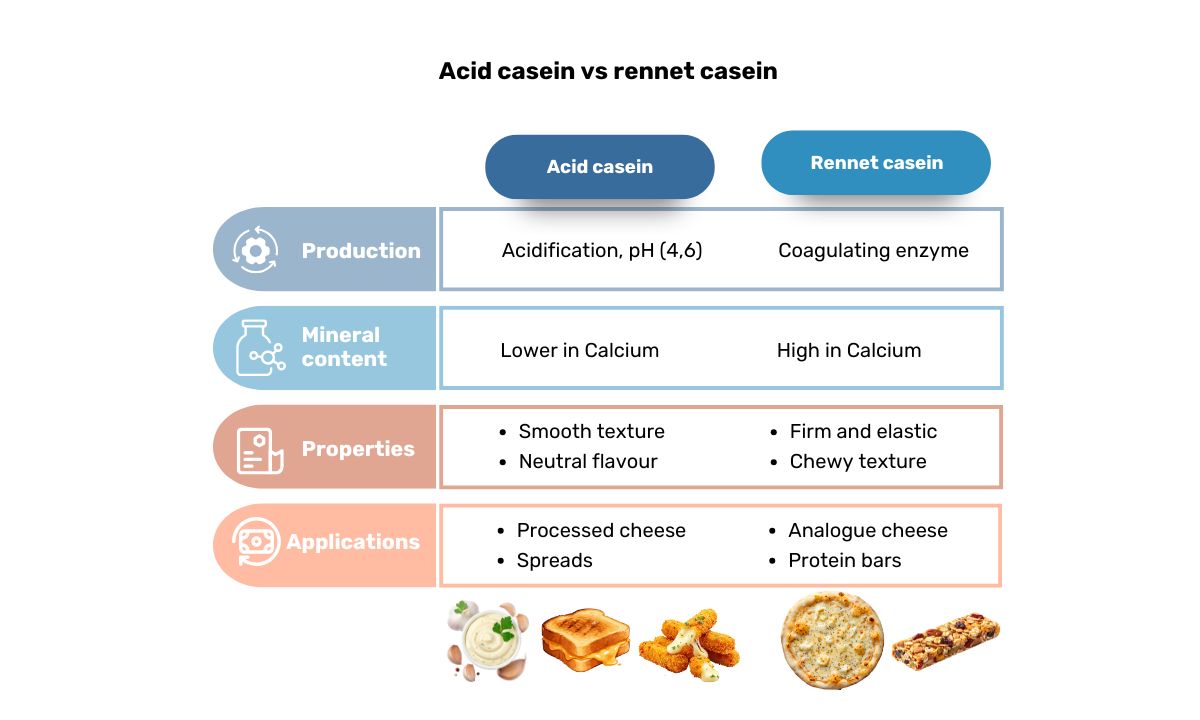

Casein is the major source of protein in cow’s milk, representing around 80%, while whey accounts for a smaller proportion (20%)[1]. This includes different kinds (αs1, αs2, β, and κ-casein) which, in milk, are found not in dissolved form but assembled into micelles[2], colloidal particles stabilised by calcium phosphate and κ-casein. The micellar structure is sensitive to environmental conditions (pH, salts, calcium, presence of enzymes). This explains why, depending on the industrial production method, a distinction is mainly made between acid casein (precipitated by acidification – at ~pH 4.6) and rennet casein (coagulated by enzyme action[3]), as each has different properties[4].

Nutritional profile of casein

From a nutritional standpoint, casein is a high-quality milk protein because it provides all essential amino acids (EAAs) in a generally well-balanced profile, regardless of its form, whether acid or rennet. The main differences lie in the mineral content, as the production process affects the levels of calcium[5].

Methods for obtaining each type of casein and functional impacts

Certain aspects of the industrial process for acid and rennet casein are the same. They both start with skim milk, which is prepared to isolate the casein from the whey. The key step is the coagulation of the micelles, which determines the nature of the casein obtained[6].

Rennet casein is produced by adding a coagulating enzyme that acts on κ-casein at a pH close to that of milk. It generally retains more calcium, which enhances structural properties such as stability, elasticity, and texture[7].

Acid casein is obtained by lowering the pH to around 4.6 (direct acidification or fermentation). This coagulation causes greater demineralisation: the casein produced is generally lower in calcium and provides a more “neutral” protein base, whose functionalities can then be adjusted (particularly through remineralisation)[8].

After coagulation, which determines the kind of casein produced, the steps become similar again: separation of the curd, washing (reduction of lactose and soluble salts), draining/pressing, drying, and then grinding to obtain a stable powder[9].

Applications specific to each type of casein

At Lactalis Ingredients, we offer both types of casein: acid and rennet. As their production methods influence their functional properties, they do not offer the same properties for formulation. Acid casein is preferred when a smooth, homogeneous matrix is required, while rennet casein is more suitable when a cohesive structure and more pronounced melting behaviour are desired.

Which casein for cheese applications?

Our acid casein is particularly suitable for processed cheeses, cheese spreads, and cheese products when seeking a smooth, consistent, and dense texture. It helps to build a homogeneous matrix with good stability. Another advantage is its formulation flexibility: by adjusting the pH, salts, and overall balance of the recipe, you can control the viscosity, emulsion stability and creaminess, to achieve consistent results without graininess or separation.

Rennet casein is preferred when a cohesive matrix is required, with chewiness and a stable structure, particularly for cheese products and analogue cheeses, as well as for processed cheeses in sliced, block or portion formats. It is particularly useful for achieving certain characteristics desired in these products, such as firmness, sliceability, and grateability.

In the case of analogue cheeses, its role is particularly interesting in terms of its behaviour under heat: it promotes elasticity when melted (stringy effect) and helps to limit the release of oil during melting.

Casein for protein bar applications

Our 110 Mesh Acid Casein is recommended for use in protein/high-protein bars, providing a neutral-tasting protein base. Casein also provides prolonged release of amino acids, making it a good choice for products designed to promote satiety or recovery, while remaining compatible with protein-rich matrices.

A combination of acid casein and rennet casein is also beneficial in protein bar applications, as it produces a soft texture without hardening and a pleasant taste without bitterness, while ensuring protein content of over 30%. The main advantages of rennet casein are its high calcium content and its competitive price, making it the most cost-effective option among the dairy proteins used in the formulation of protein bars.

Conclusion

Depending on the objectives for your product, Lactalis Ingredients offers different types of casein suited to achieving the desired texture, water retention, and heat behaviour. Acid casein and rennet casein differ mainly in their coagulation method, which determines their performance: acid casein is suitable when a smooth texture is desired (processed/spreadable cheeses, dense matrices with appropriate particle size), while rennet casein is ideal for applications where a stable structure and heat behaviour are priorities, particularly in analogue cheeses for pizzas and ready meals. The challenge is therefore to align the choice of casein with the product specifications and process, in order to ensure consistent results.

A question ? Contact-us !

Sources:

[1] S.H Davoodi et al., Health-Related Aspects of Milk Proteins, 2016.

[2] Chanokphat P., Casein micelle structure: A concise review, 2005.

[3] Gulzar Ahmad Nayik et al., Milk proteins: chemistry, functionality and diverse industrial applications, 2024.

[4] Gulzar Ahmad Nayik et al., Milk proteins: chemistry, functionality and diverse industrial applications, 2024.

[5] Abdullah Bademal et al., Production of caseins and their usages, 2017.

[6] Jonathan O’regan et al., Milk Protein Products | Caseins and Caseinates, Industrial Production, Compositional Standards, Specifications, and Regulatory Aspects, 2011.

[7] Costas.E Stathopoulos, Dairy-based Ingredients, 2008.

[8] Costas.E Stathopoulos, Dairy-based Ingredients, 2008.

[9] Jonathan O’regan et al., Milk Protein Products | Caseins and Caseinates, Industrial Production, Compositional Standards, Specifications, and Regulatory Aspects, 2011.