Optimizing Analogue Cheese: The Key Role of Rennet Casein

A market in full transformation

Originally developed to meet economic constraints, analogue cheeses have become essential ingredients in processed foods, particularly in fast food, which is rapidly expanding in countries without local milk collection. Driven by North America, the global analogue cheese market is experiencing sustained growth, with an estimated CAGR of 6% by 2035.

Imitation Pizza Cheeses : A technological alternative to mozzarella

These recombined products, manufactured through a cook-and-blend process, aim to replicate the functional properties of low-moisture mozzarella: stretchability, browning, spreadability, free oil formation, etc. Their formulation relies on a blend of ingredients such as water, vegetable fats, dairy proteins (including rennet casein), melting salts, and sometimes starch or cagliata (an unspun curd derived from mozzarella). Final performance depends on both the choice of raw materials and processing parameters (shear, temperature, cooling).

Three main formulation families

As part of our study on the functional qualification of a new rennet casein reference from Lactalis Ingredients, we explored three major formulation bases for imitation pizza cheeses:

1. Rennet casein + vegetable fat

2. Rennet casein + starch + vegetable fat

3. Rennet casein + cagliata + starch + vegetable fat

Cagliata can be used to enhance the cheesy flavor. It also plays a key functional role, particularly in texture, stretchability, and the visual appeal of the finished product.

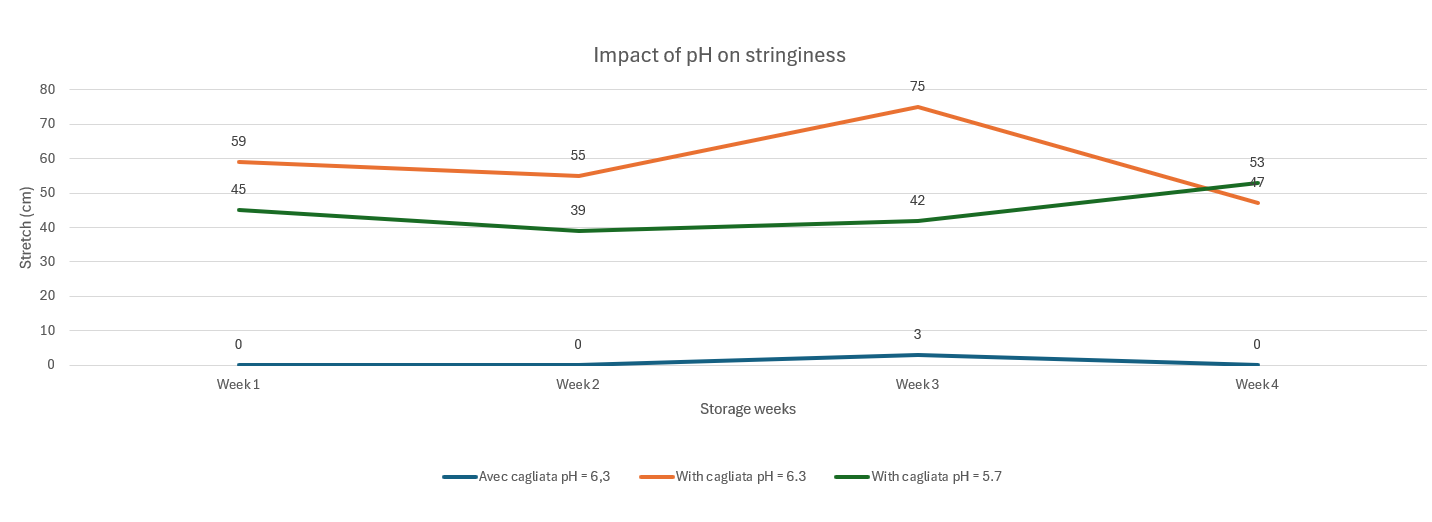

pH: A Key Lever for Performance

The trials highlighted the critical importance of precise pH adjustment for each type of formulation. This parameter directly affects texture and behavior during remelting:

- pH too low: brittle texture, poor stretchability (often caused by the addition of cagliata, which is relatively acidic, if no corrective measures are taken)

- pH too high: runny texture, “sauce-like” effect (can occur if citric acid is lacking to stabilize the pH)

- Well-adjusted pH: results in a product with good stretchability, striking the right balance between brittleness and excessive softness. It also helps optimize the visual appearance—namely browning and oil release.

Below are the target pH values identified to maximize functional properties:

| Formulation | Target pH after 1 week |

| With cagliata | 5.7 |

| Without cagliata | 6.3 |

While starch does not directly impact pH, melting salts and cagliata can alter it. Therefore, precise management of these parameters is essential to ensure product stability and performance.

Specific adjustments based on the recipe

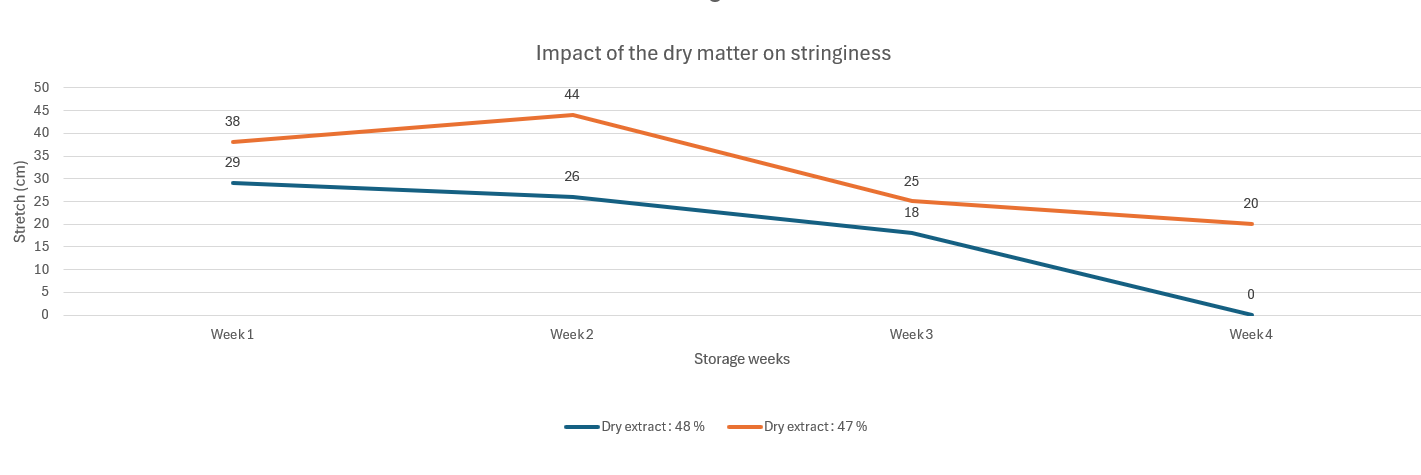

Formulation without starch or cagliata:

This base highlights the structuring role of rennet casein. It provides a firm texture but can become brittle if the dry matter content is too high. Our trials showed that by slightly lowering the dry matter from 48% to 47%, a more flexible structure is achieved, with improved stretchability and more consistent resistance to pulling.

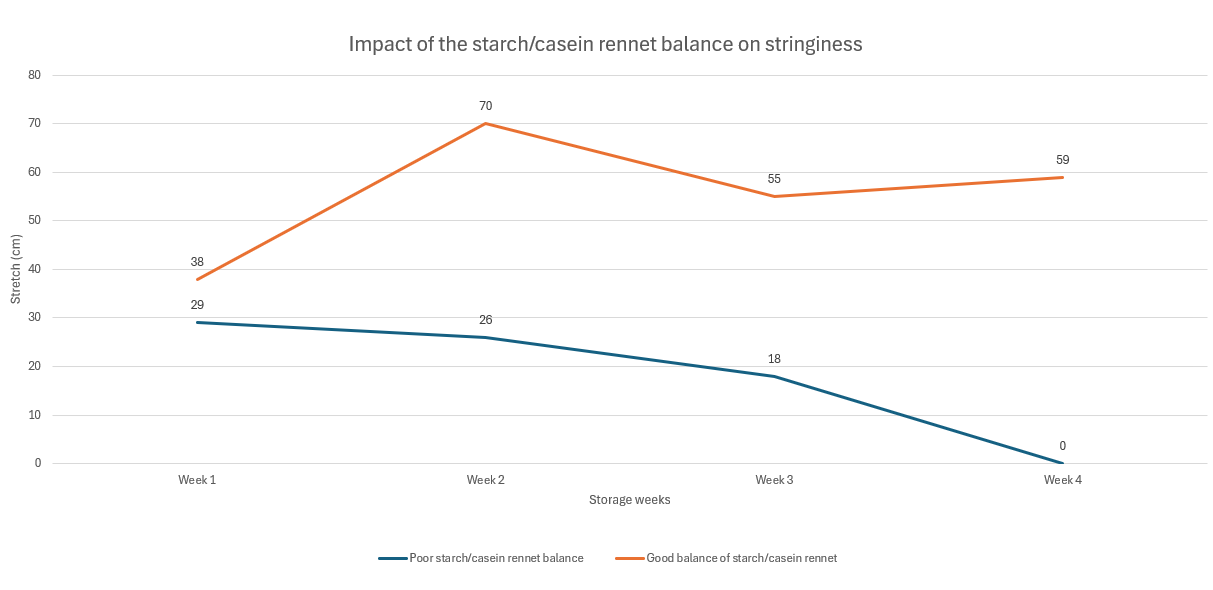

Formulation with Starch

Adding starch helps soften the texture, but it reduces the concentration of functional proteins. It is therefore crucial to strike a balance between flexibility and elasticity. Excessive starch content leads to a significant loss of stretchability, resulting in a pasty, non-extensible texture. By adjusting the starch-to-casein ratio, we achieved a stretch length of 70 cm on pizza, while maintaining good baking stability.

Formulation with Cagliata

Its naturally acidic pH, around 5.3, helps lower the overall pH of the recipe, facilitating access to the optimal functional range. In our trials, a target pH of 5.7 proved ideal for maximizing the product’s functional properties. Beyond its effect on pH, cagliata significantly enhances stretchability by contributing to a more elastic structure. It also improves visual appearance, bringing the product closer to mozzarella, and promotes free oil formation after baking—a desirable trait in pizza applications.

However, careful attention must be paid to pH adjustment. When pH exceeds 6.0, the product loses its structure: the texture becomes runny, with sauce-like behavior, which negatively impacts perceived quality and expected functionality. Conversely, when no cagliata is used and the target pH is set at 6.3, the product’s stretchability is maximized.

Conclusion: Expertise Driving Performance

This study confirms the central role of Lactalis Ingredients’ rennet casein in optimizing analogue cheeses. Thanks to its ability to hydrate, structure the cheese matrix, interact effectively with other ingredients, and adapt to various formulation profiles, it enables the maximization of functional properties in imitation pizza cheeses.

One key insight stands out across all trials: pH optimization is essential to ensure expected performance in terms of stretchability, spreadability, texture, and browning. Each formulation type has its own optimal operating range, and even slight deviations can compromise the quality of the final product. Mastery of this parameter—alongside other recipe components such as melting salts, cagliata, and dry matter—is therefore a critical lever for achieving industrial goals.

At Lactalis Ingredients, our expertise in dairy proteins and deep understanding of cheese-making processes allow us to support manufacturers in developing tailored, high-performance solutions that meet market demands. By combining innovation, technological mastery, and customer insight, we actively contribute to the evolution of the analogue cheese sector for our international clients.

We offer functional caseins that are ideal for processed and analogue cheese applications, ensuring uniform melting, controlled texture, and balanced flavor.

Any question ? Contact-us !