Focus casein : market insights and functionalities in processed and analogue cheese.

In a landscape where innovation and ingredient performance are central to industrial challenges, rennet casein stands out as a strategic lever in the formulation of processed and analogue cheeses. Through a dedicated webinar, Lactalis Ingredients offers an in-depth analysis of market dynamics, consumer expectations, and the technological functionalities of this essential ingredient.

Discover how rennet casein plays a key role in shaping the texture, meltability, and stability of finished products.

Processed Cheese Market: Moderate Growth Driven by Innovation

In 2024, the global processed cheese market reached 2.96 million tonnes¹. Over the past five years, the market has grown at an annual rate of 1%, a trend expected to continue through 2029, reaching 3.11 million tonnes.

While Europe and North America remain the historical strongholds of processed cheese consumption, future growth will be largely driven by Asia and Oceania, where annual growth is projected at 3%. These regions are becoming key growth engines for manufacturers seeking new market opportunities.

Key market trends

The processed cheese market is evolving under the influence of several major trends, reflecting product innovation, changing consumption habits, and shifting consumer expectations:

- Product Innovation: Development of ultra-meltable textures, introduction of bold and premium flavors such as truffle, chili, or black garlic, and the rise of convenient formats tailored to on-the-go consumption, such as mini-snacks².

- New Consumption Occasions: Increasing use of processed cheese in modern culinary applications, including street food, ready-to-assemble meal kits, and ready-to-use sauces—meeting the growing demand for convenience and speed3.

- Consumer Expectations: In Europe and North America, consumers are seeking more natural recipes with shorter ingredient lists, fewer additives, and improved nutritional profiles. This is pushing manufacturers to rethink their formulations4.

Rennet Casein: A Multifunctional Ingredient

In the world of processed and analogue cheeses, rennet casein plays a pivotal role.

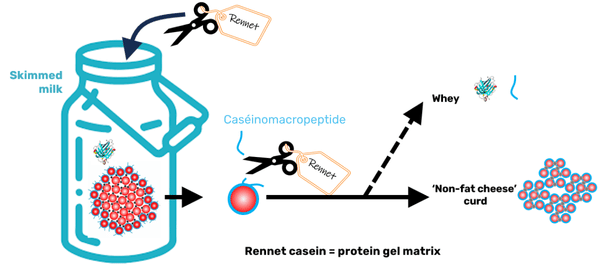

Rennet casein is obtained through the enzymatic coagulation of skimmed milk using rennet. During this process, the hydrolysis of glycomacropeptide by rennet alters the interaction properties between casein micelles, leading to their aggregation and the formation of a coagulum. Within this coagulum, the aggregated caseins largely retain their original micellar structure. The characteristic calcium phosphate bridges of casein micelles are preserved, ensuring the cohesion and integrity of the micelle. Rennet casein can be considered a fat-free cheese curd that has been washed to remove soluble minerals and lactose, while retaining the full content of micellar calcium phosphate.

Rennet casein powder is not readily soluble in water. It requires the addition of emulsifying salts to become functional. In processed cheese formulations, rennet casein is systematically combined with these salts. Once solubilized, it delivers its full range of functionalities: rebuilding a protein matrix, forming a gel, binding water, and providing emulsifying properties to stabilize fat.

Rennet Casein in Processed and Analogue Cheeses

Processed cheeses and pizza analogue cheeses are two types of “processed” cheese products that share a common base of rennet casein and emulsifying salts but differ in their manufacturing processes. Two key physico-chemical transformations are involved in both technologies:

- Peptization: This refers to the dissociation of casein micelles under the action of emulsifying salts. The micellar structure may expand or break down into submicelles. The extent of this transformation depends on the type of salt used, temperature, and mechanical shear.

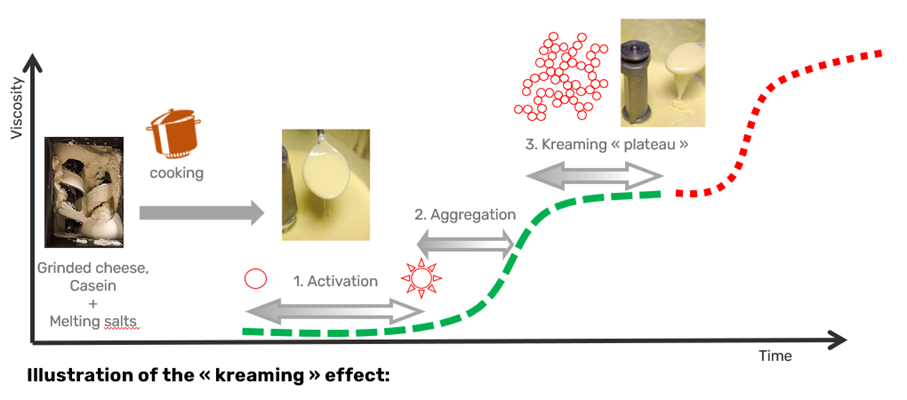

- Kreaming: This is the heat-induced aggregation of proteins, typically occurring around 80°C. It results in smooth, glossy, and heat-stable gels—characteristic of sliced processed cheeses. Kreaming is influenced by the salt type, temperature, and mechanical action.

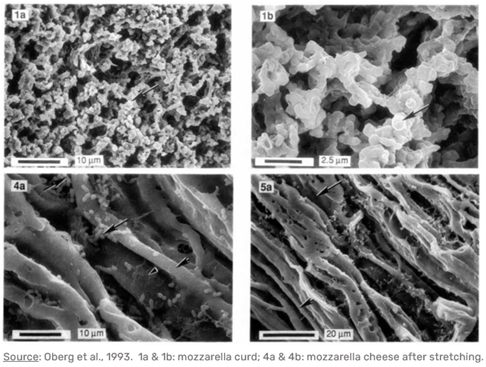

In pizza analogue cheese production, peptization and kreaming must be carefully controlled. These products aim to replicate the unique structure of mozzarella blocks, which are partially demineralized and fiber-textured. This structure gives dry mozzarella its desirable melting and stretching properties on pizza.

To achieve this in analogue cheeses, manufacturers must select a peptizing (but non-kreaming) emulsifying salt and carefully control its dosage to induce partial demineralization—essential for fiber formation. Additionally, the rennet casein used must have excellent rehydration capacity to initiate the peptization and stretching mechanisms.

The properties of rennet casein and the choice of emulsifying salt directly impact the final product. Manufacturing procedures are equally critical. Proper dispersion and hydration of rennet casein are essential to avoid texture defects, such as visible casein particles.

Subsequent processing steps must be tailored to the desired end-product. For pizza analogue cheeses, kreaming must be avoided to ensure optimal melt and spread during cooking. In contrast, for burger slice cheeses, controlled kreaming is encouraged to ensure the slices hold their shape when heated.

Unlocking Opportunities Through Deeper Ingredient Understanding

A better understanding of rennet casein offers manufacturers real opportunities: optimizing existing formulations for improved texture and yield, meeting market demands for quality, cost-efficiency, and performance, and enabling innovation with differentiated products aligned with emerging trends.

Lactalis Ingredients offers a range of caseins tailored to produce processed and analogue cheeses to meet your specific needs.

Want to learn more?

Watch our on-demand webinar for a deep dive into the use of rennet casein in cheese formulations and connect with our experts for personalized support.

Explore our dedicated cheeses page to discover the full range of products suited for this application.

Sources:

[1] Global Data. Données exclusivement issues du secteur de la distribution.

[2] FoodNavigator. (n.d.). Market trends. Retrieved July 16, 2025, from https://www.foodnavigator.com/News/Market-trends/

[3] Bokkala, P. R. (2024, September 19). Fusion foods catch consumer fancy in Asia, says GlobalData. GlobalData. https://www.globaldata.com/media/consumer/fusion-foods-catch-consumer-fancy-asia-says-globaldata/

[4] Dairy Reporter. (2024, 25 avril). Clean label dairy and consumer attitudes. https://www.dairyreporter.com/Article/2024/04/25/clean-label-dairy-and-consumer-attitudes/