Butter: an ingredient that is becoming ‘premium’

What could culinary art be without butter ?

Butter has had its place in gastronomy for a considerable time. It is an essential and unmistakeable part of French culinary culture, from the most traditional to the most modern recipes. Flavoured, incorporated, in sauces, as a mousse, in fillings, in baking, as a glaze, in biscuit making or even in pastries, butter has become essential due to its functional and organoleptic versatility.

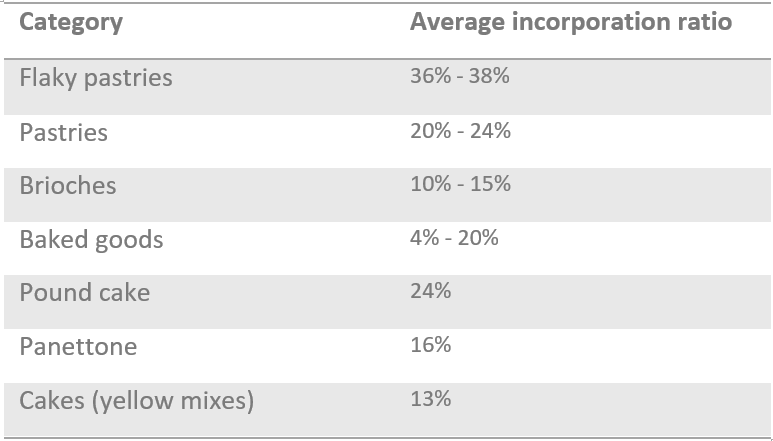

In sauces (beurre blanc, bechamel, roux), butter acts as a heat conductor, a binder, and a flavour enhancer by absorbing the aromatic and spicy notes of a mixture. In mousses, it brings firmness and consistency, incorporated into a cake it will bring flavour and moisture. Finally, in pastries and certain flaky pastries, butter play in key role in the texture and the crispiness. That is why butter can represent up to 38% to 40% of the formulation.

Table 1: Ratio of butter incorporated in pastries and baking

Pastries made with butter: the holy grail

The interest of butter is undeniable […] (it) reveals flavours and textures while acting as a technical agent making it easier to make certain recipes.

The interest of butter is undeniable: everyone agrees that butter reveals flavours and textures while acting as a technical agent making it easier to make certain recipes.

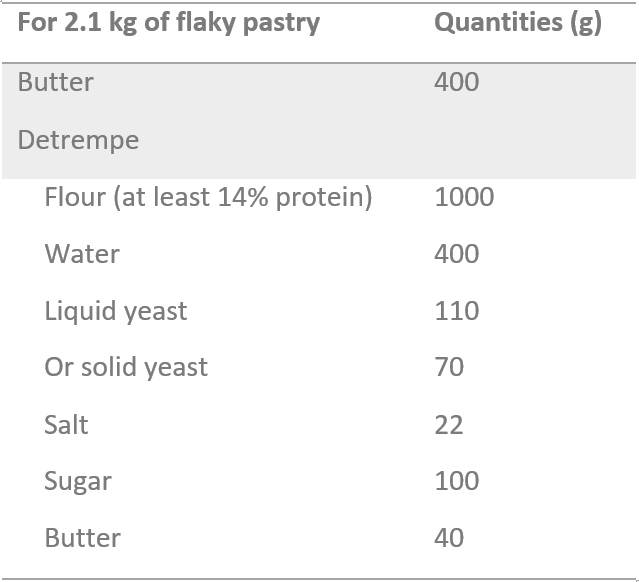

This is the case for flaky pastries, for example, where up to 40% of butter can be incorporated. In the case of more common recipes such as those below, butter represents 21% of a total of 2.1 kg of flaky pastry:

Table 2: Flaky pastry recipe examples

Before being incorporated into the detrempe, the butter must be firm yet easy to mould. Some flaky pastry manufacturers prefer to work at 5 °C to ensure that the butter is brought to the optimum temperature before it is extruded and laminated. When the detrempe comes into contact with the extruded butter, it is important to ensure a continuous butter layer so that the resulting dough/butter mixture is homogeneous. Butter acts as a physical insulator due to its lipid properties, preventing any migration of water or air from one layer to another. Consequently, during the rising and baking process, each layer of dough will swell and then brown separately making the finished product light, crisp and flaky.

Over time, butter has made its way into the eating habits of consumers all over the world: they appreciate it for its taste. Although it is often criticised for being unhealthy (causing bad cholesterol, carcinogenic, too fatty, etc.), butter has gradually recovered its reputation as an essential ingredient. Today it appeals to consumers who see it as a product that is delicious, simple, and natural, as demonstrated by the growing number of on-pack claims related to butter on biscuit and pastry end products.

Butter: a guarantee of quality and authenticity

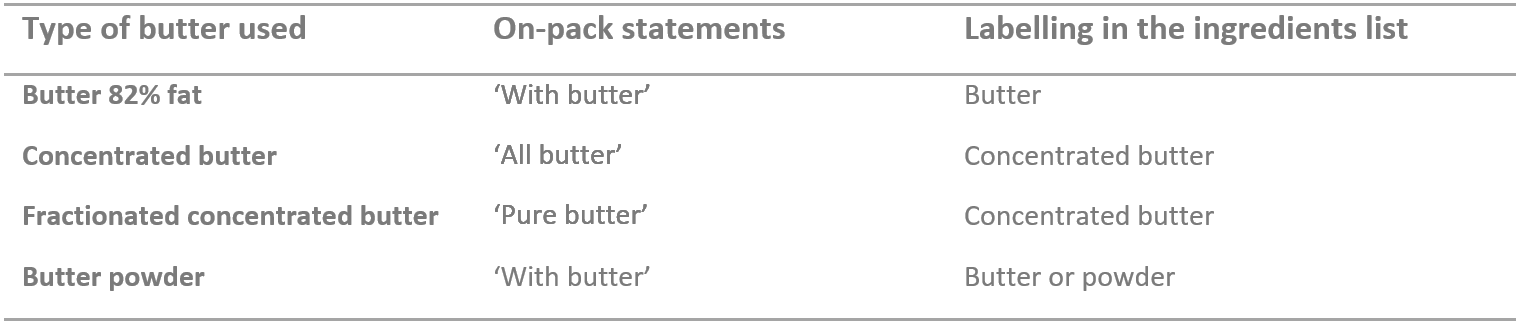

Butter is more and more recognised as a noble product, a means of promoting taste, tradition and authenticity. Butter, through its origins and production method, is still a simple, reassuring ingredient. Traditional and industrial biscuit and pastry makers can draw on the image of butter to promote their own products through ‘on-pack claims’ such as ‘with butter’, ‘pure butter’, ‘all butter’. Whether it is 82% butter, concentrated butter, or anhydrous milk fat, all qualify for these on-pack statements. The only difference is the way in which they are expressed in the product’s ingredients list. In France, those statements are supervised by the French regulation.

Table 3: On-pack statements promoting butter – french regulation

Today, the number of products with butter-related claims is increasing, and they can be found on everything from cakes, biscuits and buns to flaky pastry and pastries. The popularity of butter is universal. Initially a cornerstone of French gastronomy, it has spread throughout the world thanks to the increased emphasis on premium pastry products.

To further highlight the quality of the butters used and reinforce the use of certain on-pack claims, butter itself can be the subject of several different names aimed at strengthening its distinctive qualities.

According to French regulations:

-

- Extra fine butter is butter made exclusively from fresh cream (not frozen cream or frozen butter). It has not undergone any treatment other than pasteurisation, or any other processing (freezing, blending, overrunning, etc.). It must be made within 72 hours of collection of the milk at most or 48 hours after skimming.

- Fine butter is a butter made from at least 70% ‘fresh’ cream, so it can be made with up to 30% frozen cream.

- Fresh butter is an extra fine butter which may not be used in the finished product for more than 30 days.

- PDO butter guarantees a regional origin according to precise geographical specifications (Poitou Charentes, Isigny Saint Mère, Bresse)

- Beurre de France must be made only from French milk and cream and manufactured in France.

However, these butter qualities require a continuous flow of cream, which tends to complicate the activity of certain butter factories such as Lactalis Ingredients. Indeed, as mentioned in our previous article on butter, milk fat is a cyclical product that depends on the seasons and the cows’ gestation periods. At certain times of the year, supply of cream is limited. Furthermore, the composition changes. It is therefore difficult to ensure the long-term availability and consistency of these very specific butters without setting up dedicated storage systems, which could run counter to the quality requirements of these butters.

Lactalis Ingredients has therefore opted for a constant supply and quality butter throughout the year to sustainably meet the requirements of its clients, particularly those in the pastries sector.

What about the future ?

The pastries and biscuit sectors have been forced to review their products by reducing the quantity of butter

The current shortage of cream on the market is a cause for concern. The balance between supply and demand has been turned upside down. With world milk collection slowing down and milk fat levels dropping while demand for butter remains very dynamic, markets are under pressure. Prices are soaring. In February 2022, inflation was almost 60% over two years. This situation is of concern to butter-consuming manufacturers; the pastries and biscuit sectors have been forced to review their products by reducing the quantity of butter, reducing portions, etc., while incorporating the increase in the price of raw materials in that of their finished products.

The inflationary conditions at the beginning of 2022 raise the issue of whether the market will be able to recover a balance and reasonable prices… In the coming months? In the coming years?