Importance of casein in sweetened creamers formulations

Sweetened condensed milk is a processed dairy product that was invented in the United States back in the 1850s. This invention was an immediate success; Europe followed the lead of the United States in the 1860s, launching into the manufacture of a product that extended the shelf life of milk and facilitated its distribution.

Sweetened condensed milk: a popular product

Sweetened condensed milk soon became popular around the world, in particular in the colonies of European countries. Since then, sweetened condensed milk has become a staple part of the diet in many regions around the globe. In Asia in particular sweetened condensed milk is a very popular product, used in a wide variety of recipes for both food and drinks.

In those parts of the world that do not have liquid milk from which to produce sweetened condensed milk, local production has met the challenge by developing “recombined” products using milk powder. This new technology consists in reconstructing a recipe with a mix of powders, water and fat and has progressively widened the range of possibilities for formulated products. In fact, while it is entirely possible to reproduce the composition of a traditional sweetened condensed milk accurately using skimmed milk powder and milk fat, it is also possible to create variations of it by replacing part of the skimmed milk powder with other low-fat dairy powders and replacing the milk fat with vegetable fat. These new formulations have made it possible to create economical products that have the same uses as sweetened condensed milks.

Which ingredients are used to formulate these “recombined” products?

These products tend to be marketed with names such as “sweetened condensed creamer” or “sweetened creamer” to distinguish them from standard sweetened condensed milks; typically, they contain 40 % to 50 % sugar, 8 % to 10 % vegetable fat, 12 % to 18 % low-fat dairy powder (as opposed to 20 % to 21 % skimmed milk powder in a recombined concentrated milk) and texturizers to compensate for the reduction in dairy solids, with the last constituent being water. Four types of low-fat dairy powders are suitable for these formulations, the first being skimmed milk powder, which is the reference ingredient; the others are buttermilk powder, which has a composition that is very close to that of skimmed milk powder, then sweet whey powder and whey permeate powder, with compositions that are significantly different from that of skimmed milk. Where the cost of the formulation is to be reduced, the percentage of skimmed milk powder is decreased, the difference being made up with sweet whey powder or whey permeate powder.

Lactalis Ingredients study: understand the impact of different low-fat dairy powders in this type of formulation

Sweetened creamers have sometimes been found to have stabilization defects: creaming of the emulsion, phase separation and gelation, notably. Since these stabilization problems very rarely occur in recombined sweetened condensed milk recipes, the question arises as to the extent to which the reduction of the skimmed milk powder content and the substitution of whey or whey permeate powders is responsible for these destabilization effects.

Lactalis Ingredients conducted a study to examine the impact of different low-fat dairy powders in this type of formulation. We created a reference formulation containing skimmed milk powder and no texturizer. Then we replaced the skimmed milk powder with whey powder and/or whey permeate powder, still with no other ingredients or additives (no addition of texturizers).

Our study allowed us to make two observations

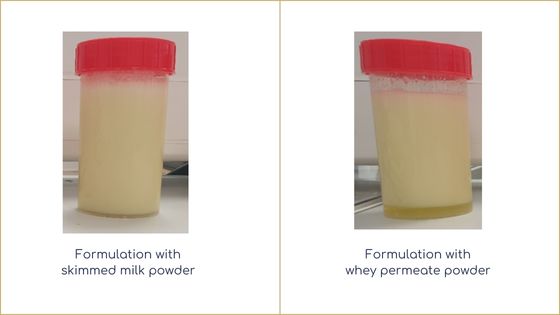

1- When the modifications to the reference formulation are pushed to the extreme so that all the skimmed milk powder is replaced with whey permeate powder, the sweetened creamer is no longer stable. A very marked phase separation can be observed (Figure 1).

Figure 1: Observation of sweetened creamers 15 days after fabrication

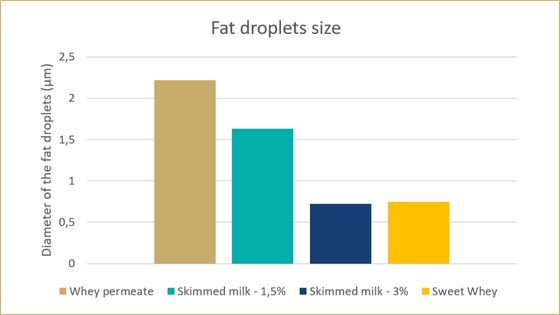

This destabilization of the whey permeate formulation can be explained by the fact that the emulsion in this version is significantly coarser, as can be seen in the graph showing the measured size of the fat globules in the different products (Figure 2). This leads to an accelerated creaming phenomenon, which causes phase separation visible to the naked eye.

Figure 2: Fat droplets size in the different products

The whey permeate also differs from the skimmed milk and sweet whey in the fact that its nitrogen fraction is essentially composed of peptides and not intact proteins. This explains the lower emulsifying capacity for an identical nitrogen fraction.

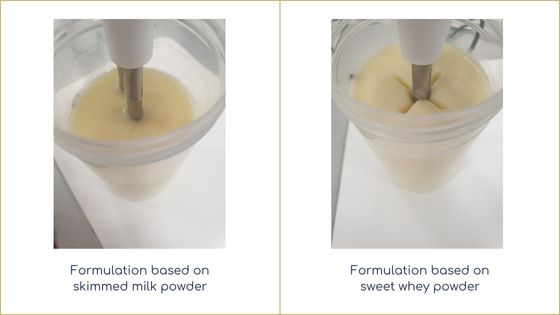

2- To take our investigation further, we wondered whether the nature of the proteins might also play a role. When substituting skimmed milk powder with sweet whey powder the protein content may remain the same, but the casein is replaced by whey proteins. Our tests showed that the formulation containing only sweet whey led to gelation when stored, whereas the reference formulation kept a viscous, non-gelled texture (Figure 3).

Figure 3: Evaluation of the texture of sweetened creamers 15 days after fabrication

Our recommendations for the creation of stable sweetened creamer formulations

1- It is necessary to meet a defined protein content threshold for the formulation.

2- It is also necessary to meet a defined casein content threshold for the formulation. Our tests enabled us to determine that this content threshold for casein corresponds to 3 % skimmed milk powder in the formulation (giving 0.8 g of casein).

A project ? Contact us for more information!