Lactose and purity: what does it mean?

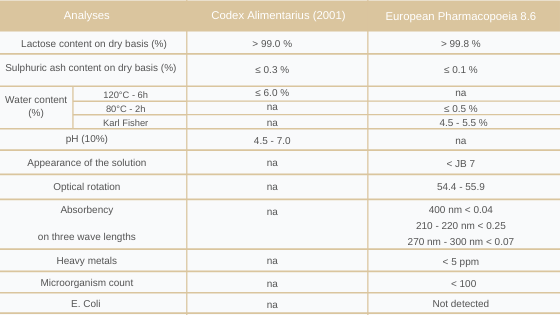

Lactose powders come in different grades depending on the market and the application, e.g. for calf feed, human consumption, infant milks, or pharmaceuticals. The lowest purity is useful mainly for animal feed whereas the highest purity is required for use in pharmaceuticals. The table below gives some specifications for food-grade or ‘edible’ lactose according to the Codex Alimentarius (2001), and pharmaceutical-grade lactose in accordance with pharmacopoeia (British Pharmacopoeia, 2001; US Pharmacopoeia, 1995).

The higher the lactose level, the purer the lactose is considered to be.

Table 1: Regulatory definition of lactose

The higher the lactose level, the purer the lactose is considered to be. Of course, the microbiological quality and chemical purity are specific to each category of lactose and will strongly depend on industrial expertise and consequently on controlling the different production stages.

-

-

- Control of raw materials (whey, permeate, etc.). This step is paramount. They are as many types of whey as there are varieties of cheese. Yet the biochemical composition of the whey to be processed has a strong impact on the different stages particularly on lactose crystallisation. Indeed, there are several components that prevent crystallisation. Generally speaking, the presence of compounds that are more hygroscopic than lactose hinders crystallisation. These include ammonia, urea, non-protein nitrogen (NPN), and soluble minerals (NaCI, KcI, etc.). Similarly, proteins strongly influence lactose crystallisation kinetics. The higher the protein content, the smaller the crystals, which is an advantage for whey powder, but a disadvantage when producing lactose powder. Riboflavin, also known as vitamin B2, a compound that is well known for giving whey its yellow colour, is also a compound that hinders crystallisation.

-

-

-

- Control of preprocessing operations: Techniques for physical and chemical separation are essential in improving the composition of the dairy liquid to be processed for the purpose of producing quality lactose powder.

-

-

-

- Control of vacuum evaporation concentration. Although this is tested technology, the concentrate’s temperature, viscosity, and dry matter content resulting from this stage will influence the following lactose crystallisation stage.

-

-

-

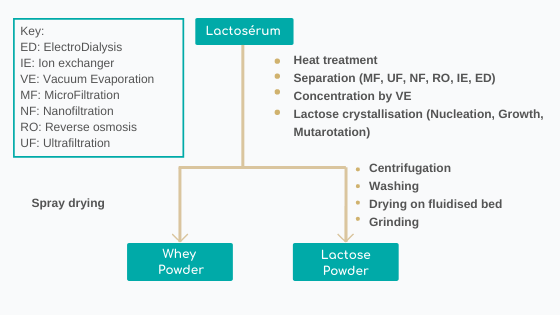

- Control of lactose crystallisation: this stage should produce many large lactose crystals in monohydrate a The three key steps for this to occur are Nucleation then Growth, and alongside growth, Mutarotation. Without nucleation, there will be no growth and no crystals; without mutarotation, there will not be a high crystallisation level.

-

Nucleation is defined as the formation of nuclei forming the core development of a new physical or chemical structure (lactose crystals for example), in an environment with a defined structure and composition. Nucleation is said to be homogeneous if the nuclei are evenly distributed.

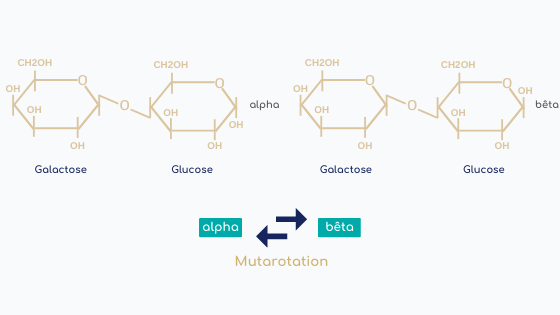

Mutarotation can be described as the change in the optical rotation between two forms, alpha and beta, in order to maintain a certain chemical balance.

Figure 1: Lactose Mutarotation

-

-

- Control of centrifugation: the lactose crystals need to be separated from the stock solution to start purifying the lactose. Centrifugation is followed by the washing stage.

-

-

-

- Control of washing: This procedure is partly responsible for the purity of the lactose powder. Washing is essential to eliminate soluble impurities and improve the purity of lactose powder.

-

-

-

- Control of drying: this step eliminates residual water so as to reduce the water activity and increase powder conservation.

-

-

-

- Control of grinding: this allows for adjusting the particle-size distribution in the lactose powder depending on the required functionalities.

-

Figure 2: Production stages

High purity lactose and riboflavin content

The riboflavin content in milk and whey varies depending on the season, what the cows eat and the production procedures through which the whey used to make lactose is derived. The riboflavin content may vary by up to 100%.

As lactose has a strong affinity for riboflavin, it is easy to understand how much lactose purity can vary. The washing stages are therefore essential to release the lactose from the riboflavin. Lactose defined as high-quality (low in vitamin B2, ash and protein) can play a considerable role when used for producing lactose derivatives or in infant nutrition. In the first case, it is preferable to use the purest lactose possible to improve yields and processing time whereas in the second case, high-purity lactose (that does not contain riboflavin) will lead to better vitamin profile regularity in infant formulas.

In conclusion, a controlled raw material will allow for optimal concentration by vacuum evaporation. This is followed by crystallisation of the lactose in its monohydrate a form with a maximum yield. Purity of the lactose is then improved via centrifugation coupled with optimised washing before finally stabilising the lactose in powder form thanks to fluidised bed drying followed by grinding, quality control and packaging.

Learn more about our lactose range here.

For more information, feel free to contact our experts.