Milk proteins interest in non dairy whipped topping

Non Dairy Whipped Toppings (NDWT) are widely used as an economical alternative to conventional dairy whipped creams. Based on a recombined emulsion made of vegetable fat dispersed in a water phase, NDWTs display excellent functional properties. By reviewing the composition of the NDWTs, milk proteins appear to be systemically used as an ingredient. Why is that so? Are they really essential? That’s the question that we propose to address in this article “Milk Proteins Interest in Non Dairy Whipped Topping”. This article is the 1st in a series of 2 articles on the subject of Non Dairy Whipped Toppings.

Non Dairy Whipped Cream: A growing market

Non Dairy Whipped Toppings are a quite dynamic and fast growing market worldwide. As mentioned before, they are positioned mainly as an economical alternative to dairy whipped cream. A significant cost reduction comes from the replacement of milk fat by vegetable fat which is cheaper. However, vegetable fat can provide not only cost savings but also functional interests. Indeed, by choosing the fat from a wide range of vegetable fat with various crystallization and melting properties, it is possible to obtain new functional properties (thermal stability, foam capacity) [1].

By reviewing the composition of a large number of NDWTs produced in different areas, we could notice that most of them hold milk proteins. Most of the time the protein content is reduced under 1% (internal benchmarking study). But obviously it seems to be essential to keep some milk proteins. We wanted to investigate why it is key to keep some milk proteins, with a focus on the emulsion properties (control of creaming and of coalescence) and on the whipping properties.

What is a Non Dairy Whipped Topping?

For a simple definition, Non Dairy Whipped Topping can be summurized as a vegetable cream. According to the Codex Alimentarius “Vegetable cream are products similar to dairy creams in which the milk fat is replaced by vegetable fat” (2). The use of non-dairy ingredients in their formulation prohibits the denomination “dairy creams”.

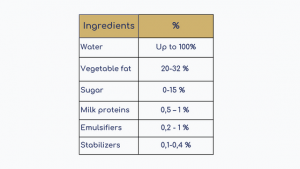

NDWTs are formulated from well-defined amounts of water, vegetable fat, milk proteins, stabilizers, thickeners, and emulsifiers. A typical recipe for NDWTs is described in Table 1.

Table 1 : NDWT typical recipe [1,3]

A balanced formulation with the good choice of functional ingredients is a key parameter to obtain a stable NDWT liquid preparation and functional whipped cream.

In this article we will focus on the role of milk proteins in NDWT stabilization.

Role of Milk Proteins in Non Dairy Whipped Topping

Whipped cream preparation can be described as an oil in water emulsion easily destabilized by whipping to incorporate air and form a stable foam [3]. The preparation of a whipped cream involves two key steps: 1- During the preparation of the recombined cream: stabilization of the emulsion and 2- during whipping: destabilization of the emulsion by partial coalescence which will then help to incorporate the air and to stabilize the foam.

Milk proteins play an essential role in these two steps.

Emulsion stabilization : formation of a stable liquid preparation

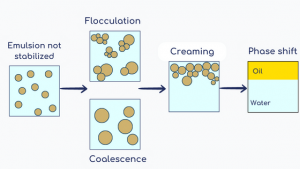

An emulsion is an unstable thermodynamic system that naturally evolves towards an equilibrium state. At its equilibrium state, the emulsion loses its dispersed state, and a phase shift (oil and water) is then observed. In the case of a NDWT, the mechanism responsible for this instability are mainly coalescence and flocculation (Figure 1)[4].

Figure 1: Non Dairy Whipped Cream destabilization mechanisms

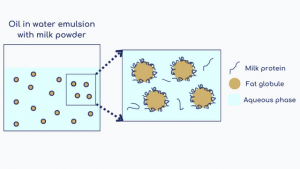

Amphiphilic molecules such as milk proteins are generally added by the manufacturers to avoid this destabilization. These proteins with a hydrophobic region are adsorbed at the water/oil interface, creating a membrane around the fat globule. This membrane acts to lower the interfacial tension between water and oil and slows down the rate at which the emulsion moves towards equilibrium. Milk proteins have a stabilizing effect through their positive impact on creaming and coalescence [4]. Milk proteins are essential in the stabilization phase of the emulsion (Figure 2).

Figure 2: Stabilization of oil in water emulsion by milk proteins

Controlled emulsion destabilization: formation of a functional & stable whipped cream

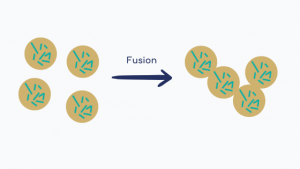

During whipping, air bubbles get dispersed into the cream. Obtaining a nice and stable whipped cream relies then on the ability of the cream to stabilize the air bubbles. The fat droplets in the cream will be key for this foam stabilization mechanism. In fact, the fat droplets need to be “pre-activated” prior to whipping in order for them to acquire their foam stabilizing properties. This “pre-activation” consists of a partial coalescence mechanism. A complete coalescence would occur when several fat droplets would come into contact of each other and would merge into one single big drop. Partial coalescence is an intermediate state between non-aggregated, individualized droplets and aggregated and merged structure. It is in fact an aggregated but non merged state. This can occur when the fat has been partially crystallized and when the interfacial film surrounding the fat droplets can prevent from a complete aggregation of the droplets (4). When fat crystals form and grow, they can break the interfacial film around the droplet and create a bridging with a neighboring droplet (Figure 3). For this crystal growth to occur, the cream has to be stored at cold temperature for some time prior to whipping. That’s what is named sometimes the “physical maturation” of the cream.

Figure 3: Partial coalescence

The role of milk proteins is to prevent the aggregated droplets from a complete coalescence. With this simply aggregated structure, the partially coalesced fat droplets can organize themselves as an elastic and resistant backbone around the air bubbles which keeps the air droplets stable and which provides the whipped cream with some consistency. The choice of a fat with a high solid fat content at ambient temperature favors partial coalescence (e.g. coconut oil, palm oil). The process of controlled partial coalescence leads to the formation of complex structures described as a protein-stabilized emulsion and a fat stabilized foam [4].

Lactalis Ingredients Applications Study: Results

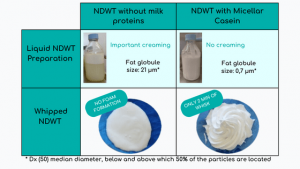

The tests carried out by Lactalis Ingredients Applications team clearly showed the importance of the role of milk proteins and notably micellar casein in the formation of a functional and stable whipped cream. The results of this study are presented in Table 2 below.

Table 2: NDWT without milk proteins and with Micellar Casein (LI Applications)

The NDWT emulsion without micellar casein is very coarse (21µm) and unstable (creaming). And it doesn’t allow the formation of a whipped cream. Conversely, the addition of 0.85 % of micellar casein in the same formulation has a spectacular impact. First it reduces a lot the fat droplet size in the cream. And secondly it allows to obtain a firm and stable whipped cream, with a very short whipping time of just 3 min. The size of the fat globules of these emulsions highlights the role of milk proteins in obtaining a fine and stable emulsion. Thus, the stability of emulsions by milk proteins is essential for the formation of a technico-functional whipped cream.

Conclusion

Milk proteins are essential for the formation of a stable Non Dairy Whipped Topping liquid preparation. The article showed that the functional properties of the whipped cream depend essentially on the stability of its liquid phase and therefore of the presence of micellar casein. In a second article, we will show that it is possible to substitute sodium caseinate, usually added in Non Dairy Whipped Topping by micellar casein.

Sources:

[1] Anihouvi P.P., Danthine S., Karamoko G. et al. 2012, Vegetal creams: An alternative to dairy creams. A review

[2] Codex Alimentarius, codex Stan 192, 1995, Carr et al.2005

[3] D. Haisman, 2011, Imitation Dairy Products

[4] H.D.Goff , 1997, Instability and Partial Coalescence in Whippable Dairy Emulsions,