Sodium caseinate VS micellar casein in non dairy whipped topping

Non-dairy whipped toppings (NDWT) consist of liquid, UHT preparations, ready to use for making whipping creams. They are formulated with vegetable fat (instead of milk cream) and with proteins and emulsifiers for the stabilization of the recombined emulsion. Sodium caseinate will typically be used as milk protein source in the formulation of liquid NDWT (observation from internal benchmark study). In this article, we will show how micellar casein can be a good alternative to caseinate in NDWT.

Is Micellar Casein the same as Caseinate?

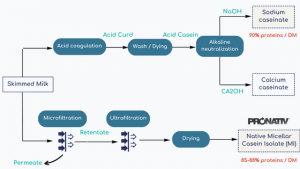

Micellar casein and sodium caseinate have in common their protein composition: they are made of casein from cow’s milk. But the structure of the casein is very different in the micellar casein compared to sodium caseinate. Their process making are different (see Figure 1). Micellar casein is obtained from skimmed milk by microfiltration, with a cold process. This very simple process allows to preserve the native structure of the casein, in its natural micellar superstructure as in milk. The process of micellar casein doesn’t need any chemical and it doesn’t produce any chemical effluent either. The casein is simply retained by the filtration membrane and it is then purified simply by “washing” the protein concentrate with water in order to eliminate some lactose and some minerals. Sodium caseinate on the other hand is not obtained directly from milk but from a curd resulting from acidification of milk. And the curd has to re-processed, with an operation consisting of a chemical re-solubilization through alkalinization with sodium hydroxide.

Micellar casein is therefore more natural and less processed. This allows to preserve a clean and milky taste which is not the case with caseinates.

With these two points of comparison – processing conditions, and taste – we believe that micellar casein can potentially make an interesting alternative to sodium caseinate for manufacturers concerned with promoting naturalness.

Figure 1: Micellar casein process making

Formulation of a Non Dairy Whipped Cream with Micellar Casein

Whippable toppings are quite complex systems, combining 5 key components: water, vegetable fat, milk proteins, emulsifiers & stabilizers. Different studies were carried out by Lactalis Ingredients application team to understand the role of each ingredient in such a complex matrix. And the interest of micellar casein has been highlighted in a previous article entitled “Interest of milk protein in NDWT application”.

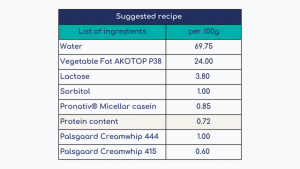

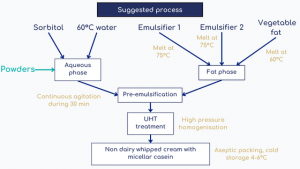

Given the large number of basic ingredients entering the composition of NDWT, the possibilities of formulating NDWTs are quite infinite. In collaboration with suppliers of vegetable fat and stabilizing systems, Lactalis Ingredients application team has been implementing an experimental design to define the optimal formulation of NDWT with micellar casein. Below in Table 1 and Figure 2 are the suggested recipe and process for NDWT coming from this collaborative work.

Table 1: NDWT suggested recipe with MCI

Figure 2: NDWT suggested process with MCI

Substitution of sodium caseinate by micellar casein in NDWT application

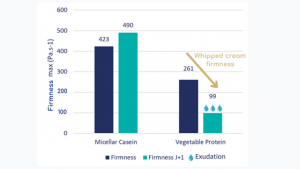

A comparative study of the functional properties of NDWT formulated from sodium caseinate and from micellar casein was carried out. The properties of the whipped creams are characterized by several functional tests including foaming capacity (overrun rate %), maximum firmness (Pa.s-1) of the whipped cream and stability of the whipped cream over time (exudation rate).

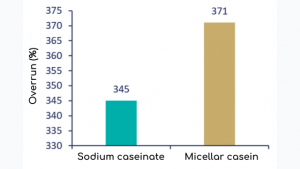

Excellent overrun rate (%) is obtained with micellar casein (Mci). We can observe in Figure 3 an increase of the overrun rate with Mci compared to caseinate. Concerning the stability of the whipped cream, there is no significant difference between recipes A (sodium caseinate) and B (micellar casein). They are both stable, with no exudation from the whipped cream.

Figure 3: Substitution of Naca by MI in NDWT: Functional properties

We introduced a commercial Vegan product (formulated with vegetable protein) as a complementary product to the experimental design in order to assess the benefits that the milk proteins can provide in the formulation of NDWT. And we found out that whipped cream prepared from this Vegan NDWT exhibited much less stability, with an important decrease in firmness and exudation rate. Obviously, milk proteins are essential for the prevention of the exudation of the whipped cream. This stabilizing functional attribute applies to both micellar casein and sodium caseinate equally.

Conclusion

This study brings evidence that micellar casein can replace sodium caseinate in the formulation of NDWT. Not only will the MCI keep the same functionalities, but it can even improve them thanks to the texturizing effect of micellar casein. NDWT formulated with MCI can provide higher yield to the end user of the UHT preparation: more whipped cream can be prepared from a given quantity of liquid ready-to-use preparation. And the whipped cream will keep excellent texture, thus good stability, and good mouthfeel. We believe that this can help the producers of NDWT to optimize their existing products or to create recipes with premium positioning.